SCHEDULE

| Dates | Venue | Category |

| 12-16 November 2023 | Doha – Qatar | Supply Chain-Procurement |

| 20-24 November 2023 | Kuala Lumpur – Malaysia | Supply Chain-Procurement |

INTRODUCTION

To maximize value from procurement, we need to combine techniques, with the appropriate tools, techniques and approaches. This Category Management in Procurement training course will provide you an effective methodology of Category Management and how this approach can be used in effectively ensuring best in class operations for Procurement Management.

Category management was first used in the retail industry to manage inventory based on profitability and customer segmentation. Now in the other industries, category management is valued as a tool to organize and effectively manage suppliers and the products through application of different principles in the acquisition of inventory.

BENEFITS OF ATTENDING

Upon the completion of this training, participants will be able to:

- Apply a thorough understanding of category management in procurement

- Identify, analyze and evaluate procurement opportunities

- Understand the keys aspects in category management

- Use tools and techniques to improve organization’s competitiveness

- Apply the knowledge in procurement and supply chain in organizational improvements

WHO SHOULD ATTEND?

- Procurement, buyers and purchasing professionals

- Those who need to maximise value from procurement and the supply chain

- Those who need an understanding of the relationships between risk, cost and service in supply chains

COURSE OUTLINE

Session 1: Understanding Procurement and Category Management

- Definition and understanding Procurement and purchasing

- Definition of Category Management

- The evolution of Category Management

- Models used in Category Grouping

- The aspects to be considered in category groups

- Managing Selective Inventory Control

Session 2: Maximising Value and Procurement Excellence using Varied Routes

- The Procurement Excellence Roadmap (PER)

- The importance of Category Management in Procurement

- Value improvement using category management

- Value Adding from Categorization

- Class Exercise on Category Management in Procurement

Session 3: Understanding the Supplier Sourcing and Selection Routes

- Traditional purchasing revisited

- Value and risk analysis

- The model in identifying inventory classification

- Best price evaluation

- Understanding collaborative supplier management

- Supplier Portfolio Analysis (SPfA)

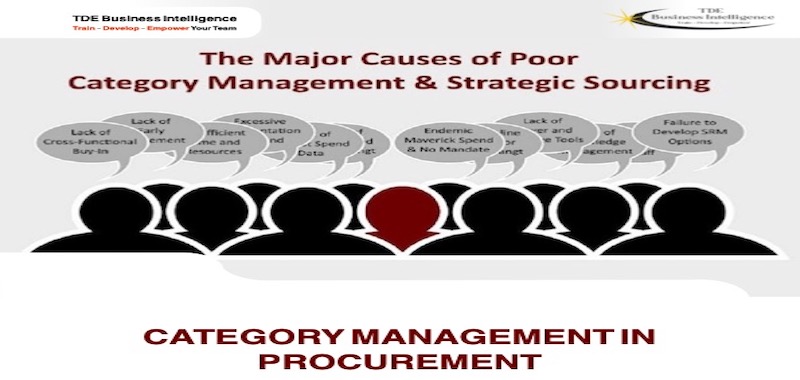

Session 4: Recognising and Overcoming the Barriers to Category Management

- Common barriers and challenges

- Overcoming such barriers

- Best Practice in the implementation of new ideas

- Managing price sensitive products

- Economic Order Quantity

- Criticality Analysis

- Class work on Selective Inventory Control (SIC)

Session 5: Category Management and Rethinking the Supply Chain

- Supply chain futures, predictions and what needs to be done

- The improvements for re-engineering end to end supply chains

- Supply chain excellence and shareholder value

- The steps to supply chain excellence

- Developing the supply chain strategy

- Supply chain strategy best practice